69 Dodge Charger Hellcat “Reverence”

TAKE A LOOK AT ALL OF THE BUILD PHOTOS BELOW!

Take a look at this quick video going over some of the areas that make Reverence truly one of a kind and then a time-lapse video of the vehicle being stripped down for paint and body work.

“REVERENCE” MADE HER FIRST PUBLIC APPEARANCE AT THE 37TH ANNUAL MOPAR NATIONALS AND THE RESPONSE WAS AWESOME. THANK YOU TO EVERYONE WHO CAME OUT AND SHOWED US SOME LOVE. HERE ARE SOME PHOTOS OF HER OUT AND ABOUT.

SCROLL DOWN TO SEE INDIVIDUAL PHOTOS OF THE BUILD IN CHRONOLOGICAL ORDER.

Here is the very solid and clean 1969 Dodge Charger that will be getting upgraded with all the power and goodies of a new Hellcat to make the ultimate MOPAR restomod

We will be using this un-hit 2016 Challenger Hellcat shell to set the 69 body onto. This will allow us to retain the all of the modern Hellcat interior and suspension parts.

Powering the 69 Charger will be this 4k mile 6.2L Supercharged HEMI removed from a 2016 Charger Hellcat.

Here is the 69 being stripped down to start mock-up for fitting the 2016 shell underneath

Here is the 69 body being mocked up on the cut and shaved down 16 shell

Here is the 69 sitting on the 2016 shell. Now its time for lots of measuring and fabrication to get everything in place.

The 69 body was pulled off of the 2016 shell and it is time to get structural. Our custom made tube steel frame rails have been fabricated to fit, mocked up, and removed to clean and paint the 2016 rockers. The rails that we fabricated were also cleaned up, prepped and painted. Stay tuned to see the frame come together.

With the cowl area fabrication getting close to completion, it is time to mock up fitment of the cooling system and the driveline.

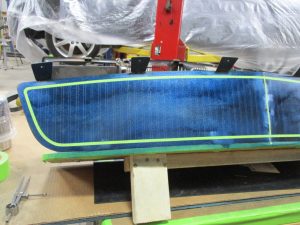

The engine and trans are mocked up in the vehicle, now it is time to add some flavor to the front end! We are fabricating a hood that shares queues from both the classic styling of the 69 and the aggressive look of the Hellcat.

With the hood design all mocked up, it is time to cut and weld! Take a look at the functional scoop and the accents on our custom hood as the are taking shape. We also did some work the the door latch and striker area to boot!

It is time to start merging the 69 Charger body and 16 Challenger body together. With the 69 Shell off of the floor pan, we finished off the rockers and painted them

After reinforcing the frame and rocker sections of the vehicle, we set the 69 body back down on the 16 floor pan to measure our gaps and check the under-hood fitment.

While doing finesse work on seems, cleaning up welds, etc we closed some gaps and started putting the finishing touches on the hood.

Back to the grind! We did some more structural work and added some clearance in the rear wheel well to allow for a larger tire. We also eliminated the pinch weld on the front aprons for hood clearance. The KW suspension arrived and rear springs are mocked up!

We made some improvements in the rear of the vehicle this week. We extended the rear rails, and did some paint/priming in quarter panel.

Finishing the rear quarter panels, cutting in the firewall, and quarter panels getting final mounting . We started fabricating the dashboard, steering column location, and checking door gaps.

We made progress on some small, yet important, fab and fit on the interior and exterior of the Charger. We modified the seat bracket on the floor pan allowing us to set the seat lower in the vehicle, allotting ample headroom for the driver. We are working on smoothing the cowl edge of the dash for a clean look. We also started mocking up the lower bumper valance and are extremely excited on this area of the car. We know this has to look perfect!

Back on the grind and putting work in on Reverence. We have been doing some mock ups of spoilers, valances, rockers, etc. She is taking shape and we are all very excited to see what she will look like in the next several weeks!

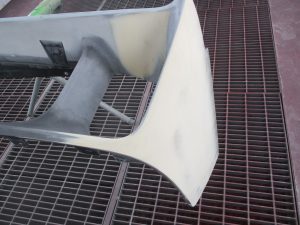

We continue the Charger build by investing time into the subtle exterior features that will make this car even more “one of a kind” than it already is. As you can see in the pictures below, we have upgraded the drivers side door handle using the new style Challenger scoop type handle, cut right out of a late model Challenger door. We have also made progress on both the rear valance and the rear wing. We even installed a backup camera! Please stay tuned for more progress pics

The rear end received more attention this week and the spoiler, lower bumper area, and valance all begin to take shape. We are excited to see some clear evidence that we made the right choice on the look of rear bumper area. We also continued with the fitment of the new style Challenger door pockets and should have all doors all squared away shortly.

The rear quarters, fenders, and rear bumper got some loving this week. Just some fabrication to pull everything together.

The rear finish panel, trunk pan, and inner wheels wells are getting closed up on the Charger! Next time she spins the tires the smoke wont pour back into the car! This is another huge step in the marrying of the two bodies. The majority of these areas will not be seen by any one other than the mechanic working on it or owner, however these areas have to look seamless and provide rigidity to the vehicles chassis.

This weeks updates include the rear bumper bar being modified, the cut outs behind the bumper bar, the inner wheel housings and radius arms, and more!

This weeks update shows the trunk gaps being property set and welded. We also started on the rocker extensions as well.

The fab work continues with the final touches being put on the inner wheels liners and trunk pan. After these pieces were fabbed up they were cut and ground to fit just right. They were painted and welded into the vehicle. As stated earlier, this area of the vehicle is rather hidden, however on a vehicle build of this caliber there is no room for cutting corners and every detail matters.

We began the task of mapping out where and how we will be mounting and routing the electronic components in the Charger. We started in the trunk, as you can see below, by fabricating mounting plates for the modules located in the rear of the vehicle. There are a good amount of electronic components that will need to be hidden in this Charger. Stay tuned for more progress.

With a good amount of wiring and electronics mapped out, we moved on to modify some of the larger interior components. Shortening the upper rear seat is a task we began to tackle. Take a look at the pictures to see how we completely disassembled the seats in order to properly cut it down to size. You will also see that we installed the upper seats strikers so that these rear seats will fold down in the car like they should. We also worked on smoothing and finishing out the fender wells and hood alignment.

This week we continued work on some small, yet important, detail work on Reverence. With the interior all pulled out of the car we were able to get at the cowl, and fabricate all of the proper panels to close it off to make it seamless. We also dove deeper into the details of the front valance by mocking up the pieces that will wrap around the sides and close off the lower nose of the car from front bumper to fender well.

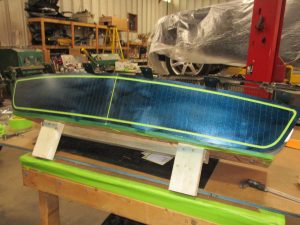

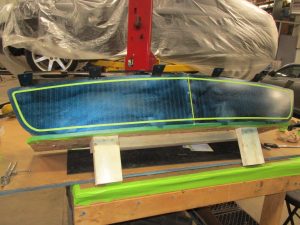

The front end on Reverence is taking shape, and looking awesome! After laying the front bumper design out on paper and loving what we saw, it was time to get to work. We fabbed up and installed front corner closeouts. We began modifying the valance, and front bumper mounts. Stay tuned to see this mean looking front end take shape. Reverence is taking shape up front!

We modified and fabricated the old and the new to allow for the mounting of a structural front bumper bar. We also closed up the firewall and finished the wiper motor surround. All the small details matter in a build of this magnitude, so even though many will never see it all of the hidden area of the car is getting the attention it deserves.

Reverence got more finishing touch work done on her this week. We also just about finished up our bumper mounts as you can see. More smoothing and grinding ahead, but we are making good progress! Back at this week adding both form and function to Reverence. We custom fabbed up some channels and mounts for some hood shocks. We also began the process of recessing the door scoops that will ultimately give the profile on this car a mean profile!

Back at this week adding both form and function to Reverence. We custom fabbed up some channels and mounts for some hood shocks. We also began the process of recessing the door scoops that will ultimately give this car a mean profile!

Reverence’s profile is looking awesome due to the recessed door scoops that are a bit deeper than originally designed. We are also working inside the car on the heater box to make sure everything fits nicely under the dash and is fully functional, and on the bumper bar making sure it will be a flush fit.

Progress on Reverence continues both inside and outside of the car this week. In order to use the factory Hellcat heat/ac system we had to get creative with the fitting the heater-box, vents and duct-work. Most of these components had to be custom made. We also made significant progress on the recessed door scoops and you can see a comparison of the before and after on the door scoop in the pics below. We also began exploring the different exhaust ideas we have in mind and got back to work on the front bumper valance.

Work on reverence continued this week with front bumper fab, door scoop/handle fab and more. Reverence is showing off her curves more and more everyday.

Door mirrors were added to Reverence this week along with major improvements on the front bumper and grille area. Stayed tuned for more progress!!

We stayed hard at work on the front end this week. We mocked up a visual of what the lower grille will look like by scribing the pattern on a template and setting it in the bumper. We also put in some work on the back of the car by starting the exhaust routing.

We put in lots of fab work this week! Take a look at the hand built and fully functional remote cooler ducts and under hood scoop that we are making. These parts, along with most of the vehicle are 100% custom fabricated and one off!

We put in lots more fab work this week! We are wrapping up on our custom, fully functional under hood scoop which looks awesome. We also worked on the dash vents and lots under the hood.

Making big progress on Reverence this week! We began the roll cage install and it is looking awesome. This cage is going to look both aggressive and sleek at the same time. We will also be installing removable door bars on this cage to allow for easy entry when the cage is not needed. We are also making progress on the dash vents as well as our custom air induction system.

This week we continued progress on the roll cage, dash area and had some fun with the engine! Our beautiful Kooks headers were installed and we threw a new pulley on the blower!

Made some exciting progress inside and outside of reverence this week! We are working hard on finishing the custom dash vents we had to make for the vehicle. We are also wrapping up the roll cage. And check out that exhaust! We piped out the exhaust and it looks awesome!!

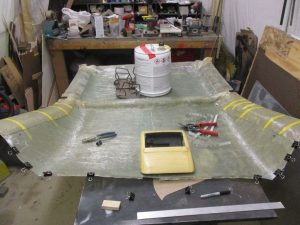

Lots of work went into these beautiful hand crafted wheel liners. We also made some progress on inner handles and door latches so our fab guys can finally get out of the car when they are done working for the day!

Reverence is looking good with progress made on her new skeleton (roll cage), while the aluminum goodies and doors get worked on. We will have the awesome LED taillights installed and operating very soon so stay tuned!

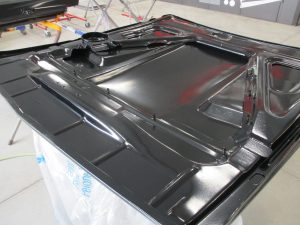

Reverence is getting her cage buttoned up and her welds ground down. We also started mockup on the under-hood close off panel as well as the front radiator cover.

Work under the hood continued this week. More progress was made on our 100% custom built and fully functional ram air hood. Our hand made core support cover is also taking shape and looking awesome. Reverence is getting all the attention to detail she deserves and will continue to be built with the highest level of detail. Stay tuned!

Reverence got to make one last stop out and about at a local townhall meeting before coming back to the shop to get torn apart and stripped down! Stay tuned for major changes in appearance!

Reverence was all torn down and everything was yanked out in order for us to media blast every nook and cranny. Here you will see the car on the rotisserie before blast followed by some shots of her underside all stripped down. We set the driveline and all essential wiring out in the shop, as if it was in the vehicle, to performance major harness surgery!

Here is Reverence blasted down and getting primed. Lots of finish work ahead!

While blasting the entire outside and underside of Reverence, we took the opportunity to blast and paint all of the suspension components.

Reverence came out of the booth primed and the guys were ready to get to work! Body panels and exterior parts were put on for the tremendous task of body working this car until it is as smooth as a 5 century old river rock!

Next stop for Reverence after the smoothing process is the paint booth for some primer time! As you can see, she has a very clean and glossy coat of primer on her, setting up for the next stage in the painting process!

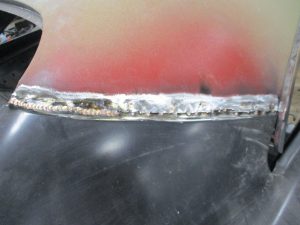

Here you will see the front fascia being smoothed down, making sure there is an even surface before being sent into the primer/paint stage. Also shown is the body of the car receiving additional smoothing before stage two of primer.

Now the front fascia enters the first stage of primer, and the body panels from Reverence go into the booth for round 2 of primer!

Shown below is the body of Reverence in between stages 1 and 2 of primer, as well as the front fascia and the door mirror after stage 2 of primer.

Reverence after stage 2 of primer , getting some touch ups as she continues to be prepped for paint.

The grille surround, doors and body of Reverence all in difference stages of primer. All of the different stages of primer assure that the body is all uniform and completely smooth.

Some shots of some different body parts, in different stages of primer. Some of the smaller items, such as the hood hinges and trunk lid hinges get their first coat of primer, as some of the other parts gets their second and third coats.

COLOR! We have color! Here you see some of the smaller items and body panels during paint cut in.

Now it’s the bodies turn for cut in, as you see the extensive taping up and covering up for that to begin.

The body of Reverence getting fitted for the custom headliner to fit around her roll bars!

INTERIOR!! Yes, here you see some various parts of the interior being worked on. The seats completely uncovered and the armrests and sill plates being constructed to fit in!

Some more interior work, as you can see the door panels, overhead console, rear seats and the sun visors all getting some work done for fitment and wrapping purposes.

Jumping around a bit, while the interior is out getting upholstered and all situated for fitment, the body was able to get the first coat of paint on! You can see the black stripe in the rear getting painted first, followed by the green coat on the rest of the vehicle!

Reverences 6 piston Hellcat calipers painted custom red with “Reverence” painted black on all four brakes. The 6 piston big brakes are necessary for stopping power required to slow down the 707 horsepower engine.

Reverences suspension with the custom painted KW Suspension adjustable lowering kit. All ready for installation!

Reverences engine and transmission all painted up and ready to roll. Complete with Kooks Long Tube Headers, the sound of everything together is going be like a lion roar!

Reverences trim pieces all laid out after being sent out to get the black chrome treatment. Also a few pictures of the front grille completed and accented beautifully with the black chrome! The grille is now ready to be put back onto Reverences body.

Back to some interior shots, as you can see the headliner getting the final touches, before getting custom wrapped. Notice the modern Hellcat touches, such as the overhead roof console and map lights incorporated into the headliner. The door panels, rear seats and pillars all getting custom wrap as well!

Onto the windshield and back glass. We used a glass coating on the windshield to crate a surface that would allow the modern rear-view mirror and associated electronics to be mounted. We did two coats, sanded the first one smooth and then did a top coat. Not only does this give the parts a surface to adhere to, it also keeps them nice and hidden from the outside when looking in.

Here, we go back to the interior for some pictures of dash, the trunk liners, cargo covers and trunk walls as well as the door panels and A-Pillars. We kept alot of modern touches thoughout this build, that includes the Harman Kardon subwoofer in the rear trunk, which coincidentally fit almost perfectly!

Some more interior work pictures. Here you see all the panels getting the wrapping treatment, as well as all stitched up. The quarter trim panels, door panels, center console shifter bezel among these items. Also shown are the door sill trim plates!

With the wave of a magic wand (or more accurately MANY labor hours),REVERENCE is complete!

Sign Up

Sign up for our email list to get up-to-date news on projects and rebuilds!

HOURS

Tuesday-Friday

6:30am-5pm ET